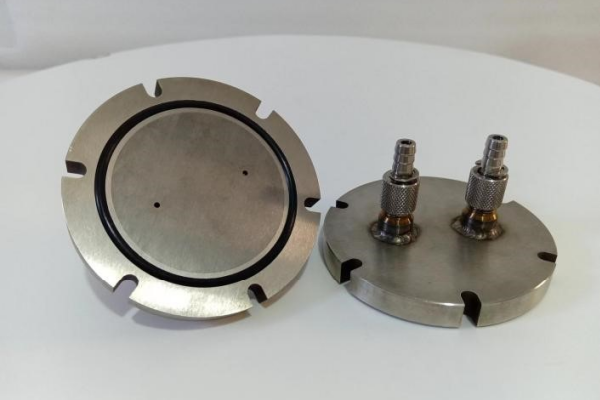

I-Tungsten Carbide vacuum Grind jar

Inkcazo

Ball mill grinding jar is mainly used in laboratories, research centers and enterprises to grind experimental samples or production raw materials, and at the same time mix, disperse and normalize ultra-fine powder processing equipment. Umsebenzi wayo oninzi, ubungakanani obuncinci, ukusebenza kakuhle, ukusetyenziswa kwamandla aphantsi, ukhuselekile kwaye uzinzile, unokubonakala kumashishini amaninzi njengezimbiwa, izinto zokwakha, i-elektroniki, njl njl.

I-Laboratory Jar Mill idla ngokugaya i-4 ye-carbide yokugaya, i-share iqhushumbe, ifuthe lelomileyo, i-Griinding ye-Driinding, okwangoku i-Goodral Groping Izixhobo zokuSebenzisa i-Ultra.

Kutheni ukhetha izinto ze-tungsten ze-tungsten ukwenza imbiza yokugaya?

Nangona iplanethi yeplanethi ye-Planethi inamandla kwaye inobuchule, i-tungsten ye-carbide ye-carbide ye-charlide i-jar ibalulekile. Inkqubo yokudibanisa kunye nokudibanisa iqhutywa kwi-carbide yebhola yempumlo, kuba i-carbide ye-carbide yebhola yempumlo iyafuneka ukuba ibe netywina elihle, elomileyo nelomileyo kwaye limanzi linokwenziwa. I-carride ephezulu yebhola ye-carfide i-jar ye-jar yeyona nto iphambili.

Isicelo

I-carbide yebhola yebhola ye-carbide ye-grindide isetyenziswa kwi-Planethi yeBhola yePlanethi, ibhola yokugaya i-carbide, isetyenziselwa ukugaya i-carbide powder, idayimane, idayimane kunye nobunye umgubo onzima.

Ikamva le-tungsten ye-tungsten ye-tungsten griting jar

I-1 .High Ukuchasana nobushushu, ubushushu bokusebenza bunokufikelela kwi-1000 ° C.

I-2.

3. High ubunzima, ubunzima obukhulu kakhulu ziimpawu eziphambili ze-carbide ye-carbide ye-carbide ye-carbide.

4 .Kreqo kunye nobunzima, kungekuphela nje kukho ubunzima obukhulu, kodwa lunobuhle kakhulu.

Inkcazo eqhelekileyo

| Ivolumu (ml) | H (mm) | I-OD (mm) | I-ID (mm) | I-LIP T (MM) | I-Wall t (mm) |

| 50 | I-61.5 | 48 | 36 | 8 | 6 |

| I-100 | 59 | 63 | 51 | 6 | 6 |

| I-250 | 69 | 86 | 74 | 10 | 6 |

| I-500 | 96 | I-105 | 92 | 14 | 6.5 |

| I-1000 | 125 | I-130 | 115 | 14 | 7.5 |

Ezinye iimveliso onokuthanda

Kukho iintlobo ezininzi ze-carbide ye-carbide ye-jars ye-jars njengezantsi:

Izibonelelo zethu

● Singumzi-mveliso esinamava angaphezu kwe-15.

● I-OEM yamkelekile.

● Iisampulu ziya kuthunyelwa ngaphakathi kweentsuku ezi-3 zomsebenzi ukuba ziyafumaneka kwisitokhwe.

● Umyalelo welingo elincinci wamkelwe kwintsebenziswano yokuqala.

● Ubungcali bezinto ezibonakalayo kwimiceli mngeni

● Ukusuka kwilebhu yophando kwimveliso ye-batch

● Izakhono zomatshini oQinisekayo

● Zonke iimbumbulu zenziwe ngaphakathi endlwini

● I-hip esekwe

● Ukuhanjiswa ngokukhawuleza 4 ~ 6 iiveki

Iinkcukacha ezithe kratya, wamkelekile ukunxibelelana nathi nangaliphi na ixesha!

Izixhobo zemveliso

Ukugaya okumanzi

Ukutshiza ukomisa

Cinezela

Cinezela

Cinezela

I-hip ye-hip

Izixhobo zokulungisa

Ukuqhuba

Ukusika ucingo

Ukugaya nkqo

I-Universal Grinding

Iplanethi igada

Umatshini wokumisa i-cnc

Isixhobo sokuhlola

Imitha yobukhuni

Umkhangi

Umlinganiso we-quadratic

Isixhobo se-cobalt

Imicroscope ye-thrografic