I-tungsten ye-tungsten ye-tungsten ye-tungsten ye-tungsten ye-tungsten ye-tung

Inkcazo

Imivalo ye-tungsten ye-tungsten ye-tungsten ye-tungsten yenziwa ikakhulu kwi-Wolfram carbide kunye ne-cobalt powder ngeendlela ze-powder. Inkqubo ephambili yemveliso ye-tungsten bar stock yi-pomder milling, milling, ukucinezela kunye nokutya. Ukusetyenziswa okwahlukileyo, umxholo we-WC kunye ne-CO kwi-tungsten carbide bar bar yerit ayifani. I-Bar ye-carbide ye-carbide ye-carbide isetyenziselwa ukuqhuba i-Grey i-iron yentsimbi, izixhobo zentsimbi ezingeyongozi, inyibiliki yentsimbi, i-PCB, izixhobo zokuqhekeza, njl.

Izicelo

1. Isetyenziselwa ukwenza izixhobo zokunganyangeki. Njengokuqubani-mveliso yokusebenza kweenkuni, ukutyhoboza kweplastiki, njl.

2. Isetyenziselwa ukwenza iindawo ezinganyangekiyo zobushushu obungaziqondisi, iinxalenye ezinganyangekiyo, iinxalenye ezikhuselweyo. Enje ngesikhokelo sololiwe wesixhobo somatshini, i-anti-ft finft yokuqiniswa kwamatshini we-ATM, njl.

I-3. Isetyenziselwa ukwenza iindawo ezinganyangekiyo kwishishini lerabha kunye neplastiki.

4. Isetyenziselwa ukwenza ubumba.

5. Iipropathi zezinto ezibonakalayo zeeplate ze-carbide ze-carbide ze-carbide ngeenjongo ezahlukeneyo azihambelani, kwaye izinto ezifanelekileyo zeepleyiti ze-carbide ze-carbide kufuneka zikhethwe ngokomsebenzi xa usebenzisa.

Inkcazo

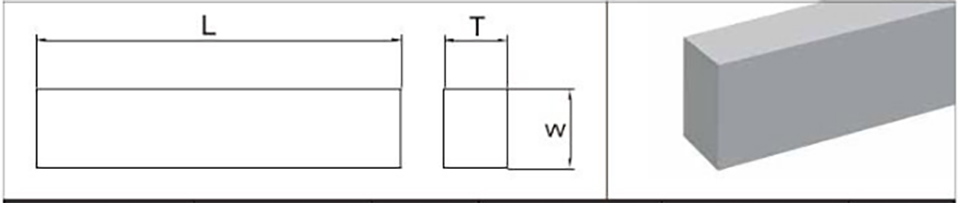

Ubungakanani obuqhelekileyo njengasezantsi:

| Ubukhulu | Ububanzi | Ubude | Ubukhulu | Ububanzi | Ubude | ||||

| mm | mm Ukunyamezelana | mm | mm Ukunyamezelana | + 1.5mm Ukunyamezelana | mm | mm Ukunyamezelana | mm | mm Ukunyamezelana | + 1.5mm Ukunyamezelana |

| 2 | + 0.3 / 0.1 | 3 | + 0.4 / + + 0.2 | I-310 | 3 | + 0.3 / 0.1 | 15 | + 0.6 / + 0.2 | I-310 |

| 2 | + 0.3 / 0.1 | 4 | + 0.4 / + + 0.2 | I-310 | 3 | + 0.3 / 0.1 | 16 | + 0.6 / + 0.2 | I-310 |

| 2 | + 0.3 / 0.1 | 5 | + 0.4 / + + 0.2 | I-310 | 3 | + 0.3 / 0.1 | 18 | + 0.6 / + 0.2 | I-310 |

| 2 | + 0.3 / 0.1 | 6 | + 0.4 / + + 0.2 | I-310 | 3 | + 0.3 / 0.1 | 20 | + 0.6 / + 0.2 | I-310 |

| 2 | + 0.3 / 0.1 | 8 | + 0.4 / + + 0.2 | I-310 | 3 | + 0.3 / 0.1 | 22 | + 0.6 / + 0.2 | I-310 |

| 2 | + 0.3 / 0.1 | 10 | + 0.4 / + + 0.2 | I-310 | 3 | + 0.3 / 0.1 | 25 | + 0.6 / + 0.2 | I-310 |

| 2 | + 0.3 / 0.1 | 12 | + 0.4 / + + 0.2 | I-310 | 3 | + 0.3 / 0.1 | 28 | + 0.6 / + 0.2 | I-310 |

| 2 | + 0.3 / 0.1 | 14 | + 0.4 / + + 0.2 | I-310 | 3 | + 0.3 / 0.1 | 31 | + 0.6 / + 0.2 | I-310 |

| 2 | + 0.3 / 0.1 | 15 | + 0.4 / + + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 5 | + 0.6 / + 0.2 | I-310 |

| 2 | + 0.3 / 0.1 | 16 | + 0.4 / + + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 6 | + 0.6 / + 0.2 | I-310 |

| 2 | + 0.3 / 0.1 | 18 | + 0.4 / + + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 8 | + 0.6 / + 0.2 | I-310 |

| 2 | + 0.3 / 0.1 | 19 | + 0.4 / + + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 10 | + 0.6 / + 0.2 | I-310 |

| 3 | + 0.3 / 0.1 | 3 | + 0.4 / + + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 12 | + 0.6 / + 0.2 | I-310 |

| 3 | + 0.3 / 0.1 | 4 | + 0.4 / + + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 13 | + 0.6 / + 0.2 | I-310 |

| 3 | + 0.3 / 0.1 | 5 | + 0.4 / + + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 15 | + 0.6 / + 0.2 | I-310 |

| 3 | + 0.3 / 0.1 | 6 | + 0.4 / + + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 16 | + 0.6 / + 0.2 | I-310 |

| 3 | + 0.3 / 0.1 | 8 | + 0.4 / + + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 18 | + 0.6 / + 0.2 | I-310 |

| 3 | + 0.3 / 0.1 | 9 | + 0.4 / + + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 20 | + 0.6 / + 0.2 | I-310 |

| 3 | + 0.3 / 0.1 | 10 | + 0.4 / + + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 22 | + 0.6 / + 0.2 | I-310 |

| 3 | + 0.3 / 0.1 | 11 | + 0.4 / + + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 25 | + 0.6 / + 0.2 | I-310 |

| 3 | + 0.3 / 0.1 | 12 | + 0.4 / + + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 30 | + 0.6 / + 0.2 | I-310 |

| 3 | + 0.3 / 0.1 | 13 | + 0.4 / + + 0.2 | I-310 | |||||

Izibonelelo

Izibonelelo zethu ze-tungsten ze-tungsten

I-1. Uzinzo oluphezulu.

I-2. Ukuchasana nengxaki kubushushu obuphezulu.

3. Ukunganyangeki kothusayo.

4. Ukuqhutywa okukhulu kwe-surmal ephezulu.

5. Ukulawulwa kwe-oxidation cerces.

I-6. Ukuchasana nomoya onamandla kubushushu obuphezulu.

I-7. Ukunganyangeki kwe-corrosion elungileyo kwikhemikhali.

I-8. Inqaku elinxibe kakhulu.

9. Ixesha elide lokutshintsha.

Iphakheji

Iphakheji yemivalo ye-calbide:

Ukuba unayo nayiphi na imibuzo, wamkelekile ukunxibelelana nathi nangaliphi na ixesha!

Izixhobo zemveliso

Ukugaya okumanzi

Ukutshiza ukomisa

Cinezela

Cinezela

Cinezela

I-hip ye-hip

Izixhobo zokulungisa

Ukuqhuba

Ukusika ucingo

Ukugaya nkqo

I-Universal Grinding

Iplanethi igada

Umatshini wokumisa i-cnc

Isixhobo sokuhlola

Imitha yobukhuni

Umkhangi

Umlinganiso we-quadratic

Isixhobo se-cobalt

Imicroscope ye-thrografic