Iqhosha le-tungsten carbide

Inkcazo

Amazinyo e-caride feride asetyenziswe ngokubanzi kwizixhobo zekhephu zekhephu zokuntywila kweoyile kunye nokususwa kwekhephu. Ukongeza, amazinyo ebhola edikekayo asetyenziswa kakuhle kwizixhobo zokusika kunye noomatshini bokuzimla, ukulungiswa kwendlela kunye nezixhobo zokuntywila kwamalahle. Amazinyo e-carbide yamazinyo asetyenziselwa imigodi esetyenziswa ikakhulu njengezixhobo ekungcungcuthekeni, imigodi, ukutyholwa kunye nezakhiwo zoluntu.

Isicelo

Iqhosha le-carbide ye-carbide lisetyenziswe ngokubanzi kwi-oyile ye-oyile kunye nokususwa kwekhephu, ukulima ikhephu okanye ezinye izixhobo ngenxa yepropathi yazo eyahlukileyo. Ngokutsho koomatshini abahlukeneyo bokuqhuba, njengeebits zeCone, izixhobo ze-DTHER, izixhobo ze-geologing, amazinyo e-carbide ye-carbide ye-carbide eyahlulelene, i-P-Flati yeBhola, isikhundla se-Z-Coin. Uzinzo kunye netekhnoloji ephezulu qinisekisa umgangatho ophezulu weemveliso zethu, amazinyo ebhola ekhatywayo ahlala esetyenziswa njengezixhobo zokuntywila, izixhobo zoomatshini kunye nezixhobo zokulungisa zendlela kwikhephu kunye nokucoca kwendlela. Amazinyo e-carbide yamazinyo asetyenziswa ngokubanzi njengezixhobo zokumbiwa ekuthinteleni, imigodi, umngxunya kunye nezakhiwo zoluntu. Ukongeza, ikwasetyenziswa njengokufanelekileyo kwe-time-don-don till yelitye okanye isixhobo sokugqobhoza esinemingxunya.

Iimbonakalo

I-carbide ye-carbide yeyona nto ilungileyo yokuvelisa amazinyo ebhola ekhadileyo esetyenziswa ngokubanzi kwishishini lokuqhuba kweDTE Sth Strill.

Iqhosha le-carbide lisetyenziswe ngokubanzi kwimigodi, ukuxabana nokusika ngenxa yobuqili babo obuphezulu. Banokusetyenziswa kwi-bits enzima.

Ibanga

| Ibanga | Ukuxinanag / cm3 | I-TRS MPA | UbunzimaHra | Isicelo |

| Cr4c | 15.10 | I-1800 | I-90.0 | Isetyenziselwa ikakhulu ukusika izinto ezinzima nezithambileyo zempembelelo. |

| Cr6 | 14.95 | Ngo-1900 | I-90,5 | Isetyenziswe njenge-bits zombane ze-coal, amalahle, iPetroleum Cone Bits kunye neeBhola zebhola yebhola. |

| Cr8 | 14.80 | 2200 | 89.5 | Isetyenziswe njenge-CRERE DRELL, DROLY COWAL PROLS, i-Coal Pekis, iPetroleum Cone Drills kunye ne-Scraper Ball -ulth. |

| Cr8c | 14.80 | I-2400 | 88.5 | Ikakhulu isetyenziswa njengezinyo lebhola eliphakathi nencinci kwaye njengokuthwala ityholo lokuhlola ukuhlola. |

| Cr11C | 14.40 | 2700 | I-86.5 | Uninzi lusetyenziswa kwiimpembelelo zokudlwengula kwaye kwi-cone drill ukusika amazinyo empumlo yezixhobo ezinzima. |

| Cr13c | 14.2 | 2850 | I-86.5 | ikakhulu isetyenziselwa ukusika amazinyo ebhola aphakathi kunye nobunzima kwi-Destrain yefuthe lokunyanga. |

| Cr15c | 14.0 | I-3000 | 85.5 | Isetyenziselwa i-oyile ye-oyile ye-oyile kunye ne-oine efihlakeleyo kunye ne-ofisi eqingqiweyo. |

Ubungakanani

I-OEM yamkelwe.

Ubungakanani obuqhelekileyo beqhosha le-tungsten njengezantsi:

| Uhlobo | Ubukhulu (mm) | ||||||||

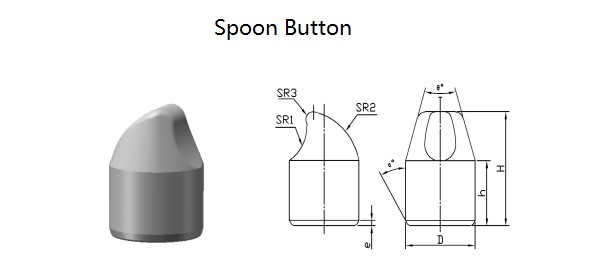

| D | H | h | Ɵ ° | Sr1 | Sr2 | Sr3 | α ° | e | |

| S1015 | I-10.25 | 15 | 9.8 | 50 | 12 | 20 | 3 | 18 | 1.2 |

| S1116 | 11.3 | 16.5 | 10.2 | 50 | 15 | 24 | 3 | 18 | 1.2 |

| S1218 | 12.35 | 18 | 11 | 36 | 20 | 25 | 2.5 | 18 | 1.5 |

| S1319 | 13.35 | 19 | 12 | 50 | 15 | 20 | 3 | 18 | 1.5 |

| S1421 | 14.35 | 21 | 12.5 | 40 | 12 | 25 | 3 | 18 | 1.8 |

| S1521 | 15.35 | 21 | 12 | 50 | 20 | 30 | 3 | 18 | 1.8 |

| S1624 | 16.35 | 24 | 13 | 30 | 15 | 20 | 3 | 18 | 2 |

| S1827 | 18.25 | 27 | 14.5 | 30 | 18 | 20 | 3 | 18 | 2 |

| Uhlobo | Ubukhulu (mm) | |||||||

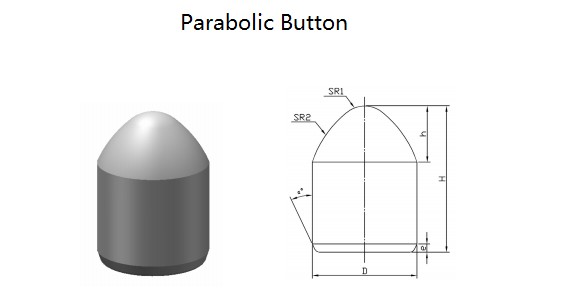

| D | H | Sr1 | Sr2 | h | α ° | β ° | e | |

| D0711 | 7.25 | 11 | 1.9 | 8.7 | 3.9 | 20 | 25 | 1.6 |

| D0812 | 8.25 | 12 | 2.5 | 9 | 4.5 | 20 | 25 | 1.6 |

| D0913 | 9.25 | 13 | 2.5 | 11 | 5 | 20 | 25 | 1.8 |

| D1015 | I-10.25 | 15 | 3.2 | 11.8 | 5 | 20 | 25 | 1.8 |

| D1117 | 11.3 | 17 | 3 | 13.5 | 6 | 20 | 25 | 1.8 |

| D1218 | 12.35 | 18 | 3 | 12 | 6.5 | 20 | 20 | 2 |

| D1319 | 13.35 | 19 | 3.5 | 13.5 | 7.1 | 20 | 20 | 2 |

| D1420 | 14.35 | 20 | 4.2 | 13 | 8 | 20 | 20 | 2 |

| Uhlobo | Ubukhulu (mm) | ||||||

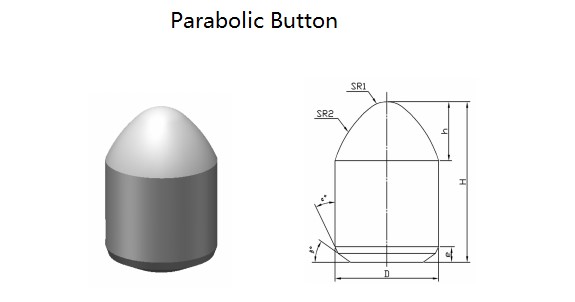

| D | H | Sr1 | Sr2 | h | α ° | e | |

| D0711A | 7.25 | 11.0 | 1.9 | 8.7 | 3.9 | 18 | 1 |

| D0812A | 8.25 | 12.0 | 2.5 | 9 | 4.5 | 18 | 1 |

| D0913a | 9.25 | 13.0 | 2.5 | 11 | 5 | 18 | 1 |

| D1015A | I-10.25 | 15.0 | 3.2 | 11.8 | 5 | 18 | 1.2 |

| D1117a | 11.3 | 17.0 | 3 | 13.5 | 6 | 18 | 1.2 |

| D1218a | 12.35 | 18.0 | 3 | 12 | 6.5 | 18 | 1.5 |

| D1319a | 13.35 | 19.0 | 3.5 | 13.5 | 7.1 | 18 | 1.5 |

| D1420A | 14.35 | 20.0 | 4.2 | 13 | 8 | 18 | 8 |

| Uhlobo | Ubukhulu (mm) | |||||

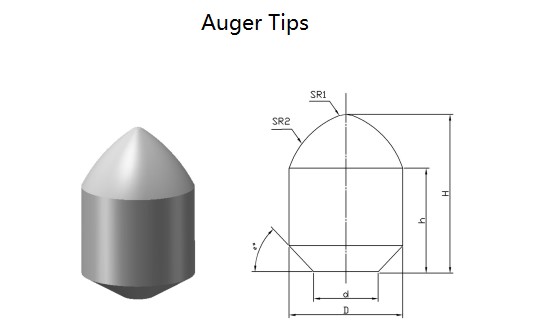

| D | d | H | h | Sr1 | Sr2 | |

| Jm1222 | 12 | 3.0 | 22 | 15 | 1.5 | 26 |

| Jm1425 | 14 | 4.0 | 25 | 17 | 1.5 | 26 |

| Jm1625 | 16 | 5.0 | 25 | 16 | 1.5 | 26 |

| Jm1828 | 18 | 5.0 | 28 | 18 | 1.5 | 26 |

| Jm2428 | 24 | 10.1 | 28 | 16 | 2 | 36 |

| Jm2534 | 25 | 18.0 | 34 | 20 | - | 25 |

| Uhlobo | Ubukhulu (mm) | |||||

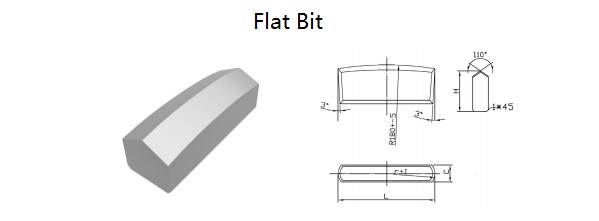

| L | H | C | r | |||

| A | B | C | ||||

| K026 | 26 | 18.0 | 15 | 12.5 | 8 | 13 |

| K028 | 28 | 18.0 | 15 | 12.5 | 8 | 14 |

| K030 | 30 | 18.0 | 15 | 12.5 | 8 | 15 |

| K032 | 32 | 18.0 | 15 | 12.5 | 8 | 16 |

| K034 | 34 | 18.0 | 15 | 12.5 | 8 | 17 |

| K036 | 36 | 18.0 | 15 | 12.5 | 10 | 18 |

| K038 | 38 | 18.0 | 15 | 12.5 | 10 | 19 |

| K040 | 40 | 18.0 | 15 | 12.5 | 10 | 20 |

| K042 | 42 | 18.0 | 15 | 12.5 | 10 | 21 |

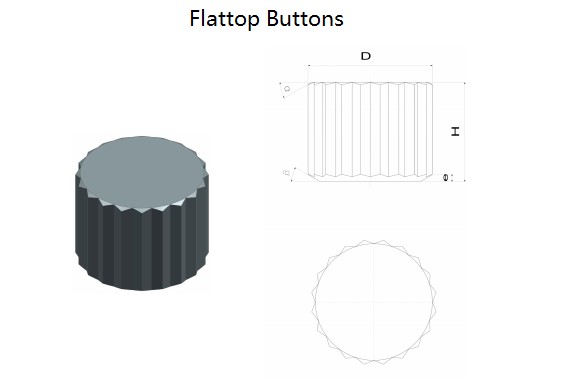

| Uhlobo | Ubukhulu (mm) | ||||

| D | H | t | α ° | e | |

| Mh0806 | 8 | 6.0 | 0.5 | 25 | 1.1 |

| Mh1008 | 10 | 8.0 | 0.5 | 25 | 1.9 |

| Mh1206 | 12 | 6.0 | 0.5 | 25 | 1.9 |

| Mh1208 | 12 | 8.0 | 0.5 | 25 | 2.5 |

| Mh1410 | 14 | 10.0 | 0.5 | 25 | 2.5 |

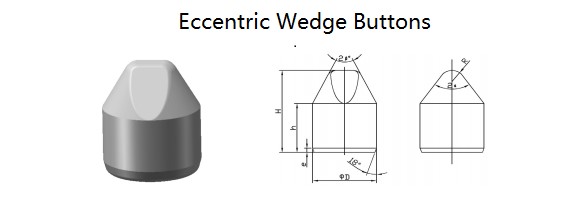

| Uhlobo | Ubukhulu (mm) | |||||||

| D | H | h | R | r | α ° | β ° | e | |

| X0810 | 8 | 10 | 6.5 | 2 | 1.8 | 45 | 22.5 | 1.5 |

| X1011 | 10 | 11 | 7 | 2.5 | 2 | 45 | 22.5 | 1.5 |

| X1013 | 10 | 13 | 9 | 2.5 | 2 | 45 | 22.5 | 1.5 |

| X1115 | 11 | 15 | 8 | 2.8 | 2.5 | 22.5 | 22.5 | 1.5 |

| X1215 | 12 | 15 | 9 | 3 | 2.5 | 45 | 22.5 | 1.5 |

| X1217 | 12 | 17 | 10.5 | 3.5 | 3 | 35 | 20 | 1.5 |

| X1418 | 14 | 18 | 10 | 3.5 | 3 | 45 | 22.5 | 1.5 |

| X1420 | 14 | 20 | 11 | 2.7 | 3 | 35 | 22.5 | 1.5 |

| I-X1520 | 15 | 20 | 12 | 3 | 3 | 40 | 22.5 | 1.5 |

| X1621 | 16 | 21 | 11 | 2.6 | 3 | 35 | 22.5 | 2 |

| X1623 | 16 | 23 | 12 | 3 | 3.5 | 30 | 18 | 2 |

| X1721 | 17 | 21 | 13 | 4 | 3.5 | 40 | 22.5 | 2 |

| X1724 | 17 | 24 | 13 | 3.5 | 3.5 | 30 | 22.5 | 2 |

| I-X1929 | 19 | 29 | 17 | 4 | 3 | 30 | 15 | 2 |

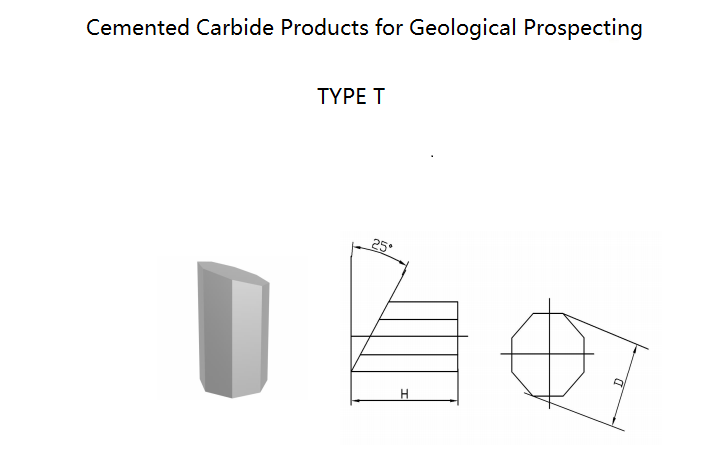

| Uhlobo | Ubukhulu (mm) | |

| D | H | |

| T105 | 5 | 10 |

| T106 | 7 | 10 |

| T107 | 7 | 15 |

| T109 | 9 | 12 |

| I-T110 | 10 | 16 |

Izibonelelo zethu

Iqhosha le-carbide ye-carbide linengxaki yokuphembelela kunye nokuba nobunzima bempembelelo, kwaye inesantya esiphezulu sokumba kunemveliso efanayo. Ubomi obungasiyo bubuncinci bumalunga namaxesha ama-5-6 ixesha elide njenge-bit kunye nobubanzi obulinganayo, oluyingenelo ukuthintela iiyure zokusebenza ezincedisayo, ukunciphisa umsebenzi wezandla kunye nokukhawulezisa isantya sobunjineli.

Ngeenkcukacha ezithe kratya, wamkelekile ukunxibelelana nathi nangaliphi na ixesha!

Izixhobo zemveliso

Ukugaya okumanzi

Ukutshiza ukomisa

Cinezela

Cinezela

Cinezela

I-hip ye-hip

Izixhobo zokulungisa

Ukuqhuba

Ukusika ucingo

Ukugaya nkqo

I-Universal Grinding

Iplanethi igada

Umatshini wokumisa i-cnc

Isixhobo sokuhlola

Imitha yobukhuni

Umkhangi

Umlinganiso we-quadratic

Isixhobo se-cobalt

Imicroscope ye-thrografic