Umtya we-tungsten ye-tungsten yenziwa ikakhulu ye-WC Tungsten ye-WC Tungsten kunye ne-Coubalt Poller exutywe yindlela ye-melverside, i-WO, i-WO, i-WC, i-CO, i-CO, i-CO, i-CO, kwaye uluhlu lokusetyenziswa lubanzi kakhulu.

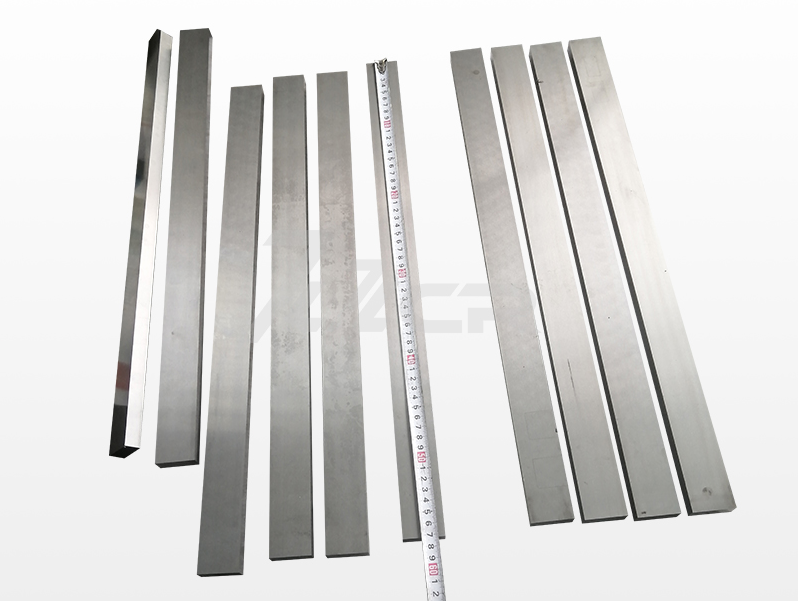

Enye yezona zinto zininzi ze-tungsten strips, ibizwa ngokuba yimo yayo engqongqo yeepleyiti (okanye izikwere), ekwabizwa ngokuba yi-tungsten ye-tungsten ye-tungsten ye-tungsten. Umtya we-tungsten ye-tungsten unobunzima obuhle kakhulu, ukunyangwa okuhle, amandla aphezulu, amandla aphezulu, ubushushu obuphezulu, i-alkali, ukwenziwa kweqondo lemikhali kunye ne-theminel kunye ne-theminel kunye ne-themoys kunye ne-themoys.

Zithini izizathu zeukungakhathaliNgomtya we-tungsten ye-tungsten? I-Chiangrui Carbide iya kuphendula ngokulandelayo:

.

(2)Ukungakhathaliziya kwenzeka xa iarhente ye-brazing ayikhethwanga kwaye isetyenziswa ngokungafanelekanga, umzekelo, xa i-borax isetyenziswa njengendima ye-razid, kwaye i-borax ayinamanzi ngaphezulu komgangatho ovuthayo, kunye neukungakhathaliI-phenomenon yenzeka.

(3) Iqondo lobushushu elichanekileyo kufuneka libe ngama-30 ~ 50 ° C ngaphezulu kwendawo yokunyibilika kwentsimbi yebrawuza,ukungakhathaliiya kwenzeka ukuba iqondo lobushushu liphezulu kakhulu okanye liphantsi kakhulu. Ukufudumeza kakhulu kunokubangela i-oxidation kwi-weld. Ukusebenzisa intsimbi ye-winc-enentsimbi ye-winc kuya kunika i-weld ngumbala oluhlaza okwesibhakabhaka okanye omhlophe. Xa ubushushu bobuqhetseba buphantsi kakhulu, kuya kwenziwa i-weld ye-weld, kwaye ngaphakathi kwe-weld kuya kugutyungelwa kukuphafa kunye nokufakelwa kwe-slag. Ezi meko zimbini zingasentla ziya kunciphisa amandla e-weld, kwaye kulula ukuDeweld xa isetyenzisiwe okanye isetyenzisiwe.

I-Post Time: Aug-28-2024