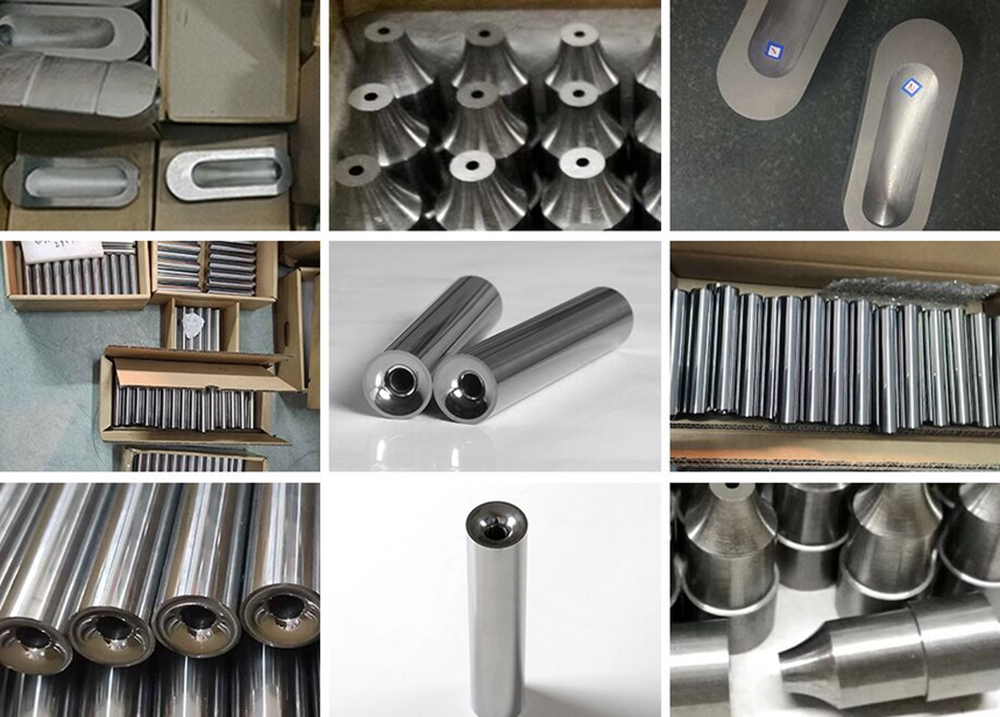

Sisoloko sibona icandelo elincinci kakhulu kwishishini lemveliso-i-nozzle, nangona incinci, indima yayo kukuba asinakutyeshela. I-nozzles zemveliso isetyenziswa ngokubanzi kukutshiza ezahlukeneyo, ukutshiza, ukutshiza kweoyile, isandula, ukutshiza kunye nezinye izixhobo, kwaye zidlale indima ebaluleke kakhulu. Ewe kunjalo, i-nozzle ibandakanya iintlobo ezininzi, ezinjenge-iron ye-cell, i-tungsten ye-tungsten, i-slicon ye-carbide, i-boron ye-carbide, i-boron ye-carbide, intsebenzo ebalaseleyo, kwaye akukho lula ukuyinxiba. Namhlanje, umhleli weChiuangrui uza kukwazisa ngokusetyenziswa kwesiqhelo kwe-nozzles.

I-carbide ye-Sandebal

I-carbide nozzles yinxalenye ebalulekileyo yesanti engapheliyo. Izixhobo ezingapheliyo zixhotyiswe ngumoya oxinzelelweyo, kwaye zitshiza izinto ezingaphezulu kwesantya esiphezulu kwi-jet ephezulu yokufikelela kwinjongo yonyango oluphezulu. Xa kuthelekiswa ne-nozzles eyenziwe kwezinye izinto, ezinjengee-nozzles zensimbi, ii-nozbide ze-carbide zinobuqili obuphezulu, amandla, zinxibe ukunganyangeki kweemeko zesicelo.

I-carbide neezzzles zeoyile

Kwinkqubo yokuqhuba ioyile, ngokubanzi kubume obuthile, ke i-nozzle ifuna ukumelana nefuthe eliphezulu lokucinezelwa ngexesha lokusebenza ngexesha lenkqubo yokusebenza, ethambekele kakhulu yokunxiba kunye nokusilela. Izixhobo eziqhelekileyo zithambekele ekusetyenzisweni kwe-thermal okanye ukuqhekeza, kwaye i-nozzles kufuneka itshintshwe rhoqo, enciphisa ukusebenza kakuhle. Ii-carbide ii-nozzles zinokungcono ziphucule le meko ngenxa yobukhuni babo obuphezulu, amandla aphezulu kunye nokuhlaselwa kakhulu kunye nokunganyangeki.

I-carbide nozzzle ze-CWS

Xa i-colry yamalahle i-colry isebenza, iphantsi kwe-errosion ye-angle ephantsi ye-colry ye-colry, kwaye indlela yokunxiba ikakhulu yingqokelela yeplastiki kwaye ihlawulwe ngamancinci. Xa kuthelekiswa ne-cews ye-callsles eyenziwe ngezinye izinto zensimbi, ii-nozbide ze-carbide ze-carbide zinokunxiba ngcono kunye nokunganyangeki kwenkonzo ebonakalayo kwaye kubomi benkonzo (ihlala ingaphezulu kwe-1000H). Nangona kunjalo, i-carbide ye-carbide ngokwayo i-brittle, ubunzima bayo, ubunzima kunye nokungaxhathisi isothuso, akukho lula ukwenza i-noozss ngemilo yobume kunye nolwakhiwo.

I-carbide iatoming inozzle

Iifom ze-Atomizetion ze-Atomide ye-Atomide ye-Atomide inokuthi yahlulwe ibe yi-Amitomisis ye-Atomis, i-Atorical Amitos, i-Amitosticity ye-Anctrostatic, i-Atososonic Atomisis kunye ne-Amitosization yeBubble. Xa kuthelekiswa nezinye iintlobo ze-nozzles, ii-nozbide ze-carbide ze-carbide zinokufezekisa iziphumo ngaphandle kwe-compressor yomoya. Ubume be-atomisys buseke ijikeleza okanye bubunjelwe fan, kunye nefuthe elihle leatomis kunye ne-Atomisis elungileyo kunye nokugubungela ngokubanzi. Isetyenziselwa imveliso yezolimo yokutshiza kunye nokutshiza kwemizi-mveliso. Isetyenziswe ngokubanzi ekutshiyeleni, ukususwa kothuli kunye nokuvutha kwemveliso.

I-Chuangrii iphucule ngokuzimeleyo amabakala ezinto eziphathekayo ekuphuculeni ukunganyangeki kwempahla kunye nokuxhathisa kwezinto, kwaye kunike abathengi ngeendlela ezahlukeneyo ze-nozzles ezinomgangatho ophezulu kunye neenzuzo zexabiso ukujongana neemeko ezahlukeneyo zomsebenzi. Inetekhnoloji yemveliso evuthiweyo kunye ne-Advanced yeMveliso kwimveliso ye-carbide ye-carbide, ehambelana nemveliso ezenzekelayo nefanelekileyo. Ukuba uneemfuno ezifanelekileyo, nceda ukhululeke ukunxibelelana nathi.

Ixesha leposi: May-31-2023