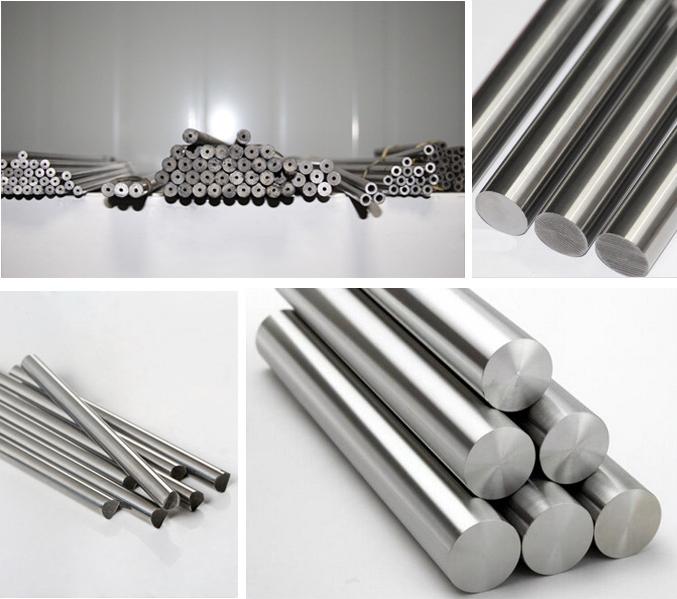

I-tungsten ye-tungsten carbide yi-tungsten carbide ye-carbide ye-carbide, ekwabizwa ngokuba yi-tungsten ber, kulula ukuyithetha i-bar ejikeleze i-bar okanye i-tungsten yentsimbi okanye i-tungsten yentsimbi ye-tungsten. I-tungsten carbide sisixhobo esihlanganisiweyo esiveliswe ngumgubo we-powder kwaye sidityaniswe izixhobo zensimbi (isigaba esinzima) kunye neentsimbi ezinamafutha (isigaba se-Binder).

Zimbini iindlela zokwenza izinto zokuveliswa kwee-carbide ze-tungsten ze-tungsten: enye iyaphelelwa, kunye nokuphuma yindlela efanelekileyo yokuvelisa imivalo emide. Ingancitshiswa nangaliphi na ixesha elide enqwenelekayo ngumsebenzisi ngexesha lenkqubo yokuphumelela. Nangona kunjalo, ubude bonke bangenakudlula kwi-350mm. Olunye lubunjiweyo, eyindlela efanelekileyo yokuvelisa ibar emfutshane. Njengoko igama libonisa, i-ceride ye-carbide powder icinezelwe ukuba ibe yimo enombungu.

I-carbide yamandla inothotho lwezinto ezibalaseleyo ezifana nobunzima obukhulu, zinxiba ngokungaguqukiyo, ukuxhathisa ubushushu, ngakumbi kunolukhuni oluphezulu kwi-1000 ° C. I-tungsten ye-tungsten isetyenziswa njengezixhobo zezixhobo, ezinje ngokuguqula izixhobo, iinyibiba ezinqabileyo, intsimbi enesitayile, i-picker, ispile, ispile yentsimbi kunye nezinye izixhobo ezinzima ( IKhabhinethi eyomisayo, i-Z-Granulator ---), icinezela (nge-HodDraulic Phydraulic Proner okanye iZiko loTyalo-mali).

Izinto ezingafunekiyo zigayile amanzi, ezomisa, iglue zenza, emva koko yomisa kwaye incitshiswe kwaye incitshiswe kwaye inciphise i-walfy okanye i-exturisoon, kwaye ekugqibeleni ingena kwi-tray.

Ukungancedi kakuhle kwemveliso yokujikeleza kwe-bar yokuphuma kukuba umjikelo wemveliso ubude. Ukuqinisa imitya emiselweyo yedayimitha encinci ngaphantsi kwe-3mm kunye nokuqhekeza ezi ziphelo zibini kuya kuchitha inani elithile lezinto. Ubude obude bobude be-carbide bude bude bubukhulu, obumangalisa ngokuthe tye kwento engenanto. Ewe, ngokuthe tye kunye neengxaki zokujikeleza zinokuphuculwa ngokugaya i-cylindrical kwinqanaba elizayo.

Omnye ukuqubuda kwe-conbud, yeyiphi indlela emfutshane yebhafu ye-bar. Njengoko igama libonisa, kukubumba ocotha umgubo we-carbide oqinileyo. Inzuzo yale ndlela yokwakha i-carbide ye-carbide kukuba ingenziwa kwi-Pass enye kwaye inciphise i-scrap. Yenza lula inkqubo yokusika ucingo kwaye ususe umjikelo wezinto ezibonakalayo zendlela yokuphuma. Ixesha elifutshane leli-lintla linokugcina abathengi kwiintsuku ezingama-7-10.

Ngokuthetha ngokungqongqo, ukucinezela kwe-isostatic nayo yeyokutsala umdla. Ukucinezelwa kwe-isostatic yeyona ndlela ifanelekileyo yokuvelisa ukuveliswa kwe-carbide enkulu nelanga. Ngomgangatho ophezulu wepiston, ongezantsi kwepuzzle, impompo yoxinzelelo ikhuphe i-winetium yolwelo phakathi kwe-cylind yoxinzelelo oluphezulu kunye nerabha exineneyo, kwaye uxinzelelo lwerabha, kwaye uxinzelelo luye lwacinezelwa.

IXESHA LOKUQALA: UJan-24-2024