Ngokwembono yokwakhiwa kweziphatho zezinto ezibonakalayo, i-robide ye-carbide ye-carbide ikakhulu ilungiselelwe inkqubo ye-powdergergy yenkqubo ye-powdergergraph ye-piclergy esebenzisa i-cultix ye-wcres, i-tungs. Njl. Njl. Le ndibaniselwano ekhethekileyo yezinto ezimbi inika i-tungsten ye-tungsten roll inqanaba eliphezulu, lidla ngokuchasene nokungakhathali okutyebileyo, ukubangela ukuba iindlela ezinobushushu obukhulu, iinkqubo eziphezulu kunye neenkqubo eziphezulu zokuqengqeleka. Uluhlu lwe-ceramic lusekwe kwizinto ze-ceramic kwaye zenziwa yinkqubo ekhethekileyo. Izinto ezimbalini ze-ceramic ngokwayo zinobunzima obukhulu kakhulu kunye nokunganyangeki kwe-cerrosion enkulu kakhulu, eyenza i-quramic roll yenze kakuhle kwinkqubo eqengqelekayo, ngakumbi kwimeko yeemfuno eziphezulu zokugqiba kunye nokunganyangeki koluhlu.

Ngokweempawu zentsebenzo, i-tungsten rolls yaziwa ngokuba kukunganyangeki kwazo kunye nokungakhathali kobushushu. Inobuqili obukhulu kunye nokuzinza okumnandi kwe-therm, kwaye kunokubaleka ixesha elide kwiqondo lobushushu eliphezulu kunye nokusinga komgangatho ophezulu, ophucula kakhulu ukusebenza kwempumelelo kwe-milly yemilitha. Ukongeza, i-tungsten ye-tungsten ye-tungsten ikwanengxaki yokuqhubela phambili kwe-sungman, enokutshintsha ngokukhawuleza ubushushu ngexesha lenkqubo, kwaye inciphise ubushushu bomphezulu we-roll, kwaye unciphise ukonakala koxinzelelo lwe-roll. Kwelinye icala, kwelinye icala, zibonakaliswa ngobuqili bazo obuphezulu, ukuxhathisa ubuchule kunye nokuzinza kobushushu obuphezulu. Ipropathi ekhethekileyo ye-ceramic yezinto zokwenza i-ceramic zenza ukuba kube lula ukuthuthuzeleka ngeekhemikhali ngexesha lenkqubo eqengqelekayo, kwaye inokugcina ukugqiba komhlaba ixesha elide. Kwangelo xesha, iiroli ze-ceramic zinokugcina ukusebenza ngokuzinzileyo kwiimeko ezinobushushu, kwaye aziyi kuphelisa okanye zithambekele ngenxa yokunyuka kobushushu kuyanda.

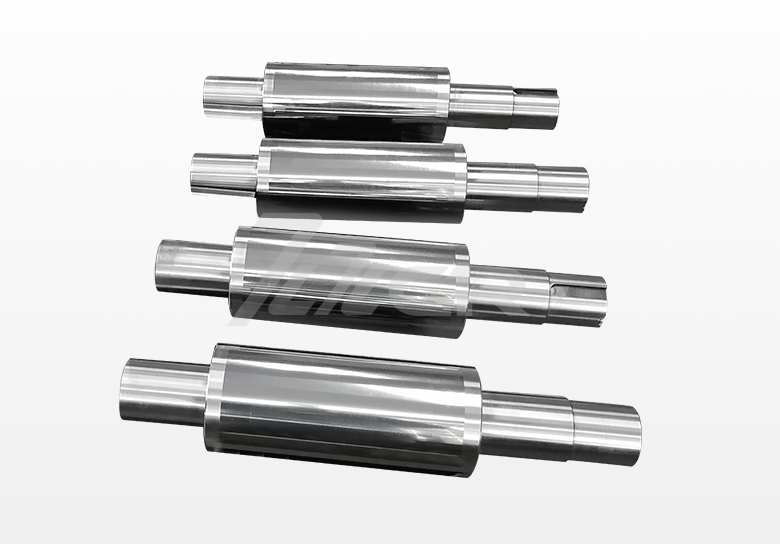

Ngokuphathelele kwisicelo, iingubo ze-carbide ze-carbide zisetyenziswa ngokubanzi kwimveliso eqengqelekayo yezinyithi zentsimbi, ezingenantlonelo kunye namanye amashishini ngenxa yezinto zabo ezintle. Ingakumbi kumandla amakhulu, iindawo ezinomthwalo ezikhulu eziqengqelekayo njengezantya eziphezulu ze-wire roll kunye nokugqiba ii-mills eziqengqelekayo, ii-rolls ze-carbide ze-carbide zidlala indima engenakufikelelwa. I-roramic roll isetyenziswa ngokubanzi kwimigca eshushu nenemigca eshushu kwishishini lentsimbi, imveliso ye-ceramic, ukulungisa kwe-elekli, ukulungiswa kwe-elekli kunye nobunzima be-elektroniki ngenxa yobuqili babo obuphezulu, ukuzinza kobushushu obuphezulu kunye nozinzo lobushushu obuphezulu.

IXESHA LOKUQALA: UPE-02-2024