I-sungssing ephezulu yokutywina ye-tungsten ye-tungsten yetywina yeTenkile yeTealical

Iimpawu zeMveliso

I-tungsten carbideIzixhoboisetyenziswa ngokubanzi ebusweni okanye amakhonkco ngokunxiba okunganyangekiyo, amandla aphezulu e-fulls, ukwenziwa kwe-sungs, i-teal yokwahlula-hlulwa kwetywina.Idaliwe cI-Arbide Seal ringyi-combalt binder kunye ne-nickel binder.I-tungsten carbide callicalZisetyenziswa ngokukhulayo kwimpompo ye-fluid ukutshintsha i-Gland kunye neTywina leLip. I-tungsten carbide yetyhubhu yetyhubhu yetywina yomatshini esebenza ngokukuko kwaye ngokubanzi yenza ngokuthembekileyo ixesha elandisiweyo.

Ngokwemo, la matywina ayabizwaI-tungsten carbide yetywina. Ngenxa yokuphakama kwe-tungsten ye-tungsten ye-tungsten, i-tungsten carbide yetywina ibonisa ubukhali obukhulu, kwaye okona kubaluleke kakhulu kukuba bayaxhathisa ukunyanzelwa kwaye baxhathisa i-rerosion. Ke ngoko, i-tungsten ye-tungsten ye-tungsten callide yoomatshini i-rings yeyokusetyenziswa ngokubanzi kunamatywina lwezinye izixhobo.tungsten ze-carbide ye-carbide ye-carbide ye-carbide inikezelwe ukunqanda i-shaft yokuqhuba. Indlela elawulwayo iphakathi kwendawo ezimbini ezithe tyaba ezihambelana neshafti ejikelezayo kunye nezindlu ngokulandelelana. I-dabies yendlela yokuvuza iyahluka njengoko ubuso buyahluka umthwalo wayo ongaphandle omele ukuhambisa ubuso bohlobo lweZindlu ngaphandle kokuba itywina lomatshini le-Shaft kuba lolunye uhlobo lwe-Shaft kunye neTywina loMatshini aliboneleli nayiphi na inkxaso kumngxunya.

I-tungsten carbide yetywina letywina liza ngeendlela ezimbini eziphambili

I-CoAbalt iboshwe (izicelo ze-Ammonia kufuneka zithintelwe)

I-nickel edityanisiweyo (inokusetyenziswa kwi-ammonia)

Ngokwesiqhelo iipesenti ezi-6% ze-Binder zisetyenziswa kwi-tungsten carbide yetywina yetywina, nangona uluhlu olubanzi luyafumaneka. I-Nickel-Bold Tungsten Carbide yeTylide yeTywina yeTywina ixhaphake kakhulu kwimakethi yamanzi amdaka amaninzi ngenxa yokuphuculwa kwezinto eziphuculweyo zeCorrosion xa ithelekiswa nezinto ezithintelweyo ze-combt.

I-tungsten carbide yokutywina kwesicelo se-ring

I-tungsten carbide yokutywina isetyenziswe ngokubanzi njenge-tywina ebusweni boomatshini, izityalo ze-petrocres, izityalo ze-petrocsilis, imigodi, ishishini lemigodi, kunye neshishini lamachiza. I-Seal-kley iya kufakwa kwimpompo yomzimba kunye ne-axle ejikelezayo, kunye neefom ngokujikeleza ubuso obujikelezayo kunye ne-teacing itywina okanye itywina le-teali.

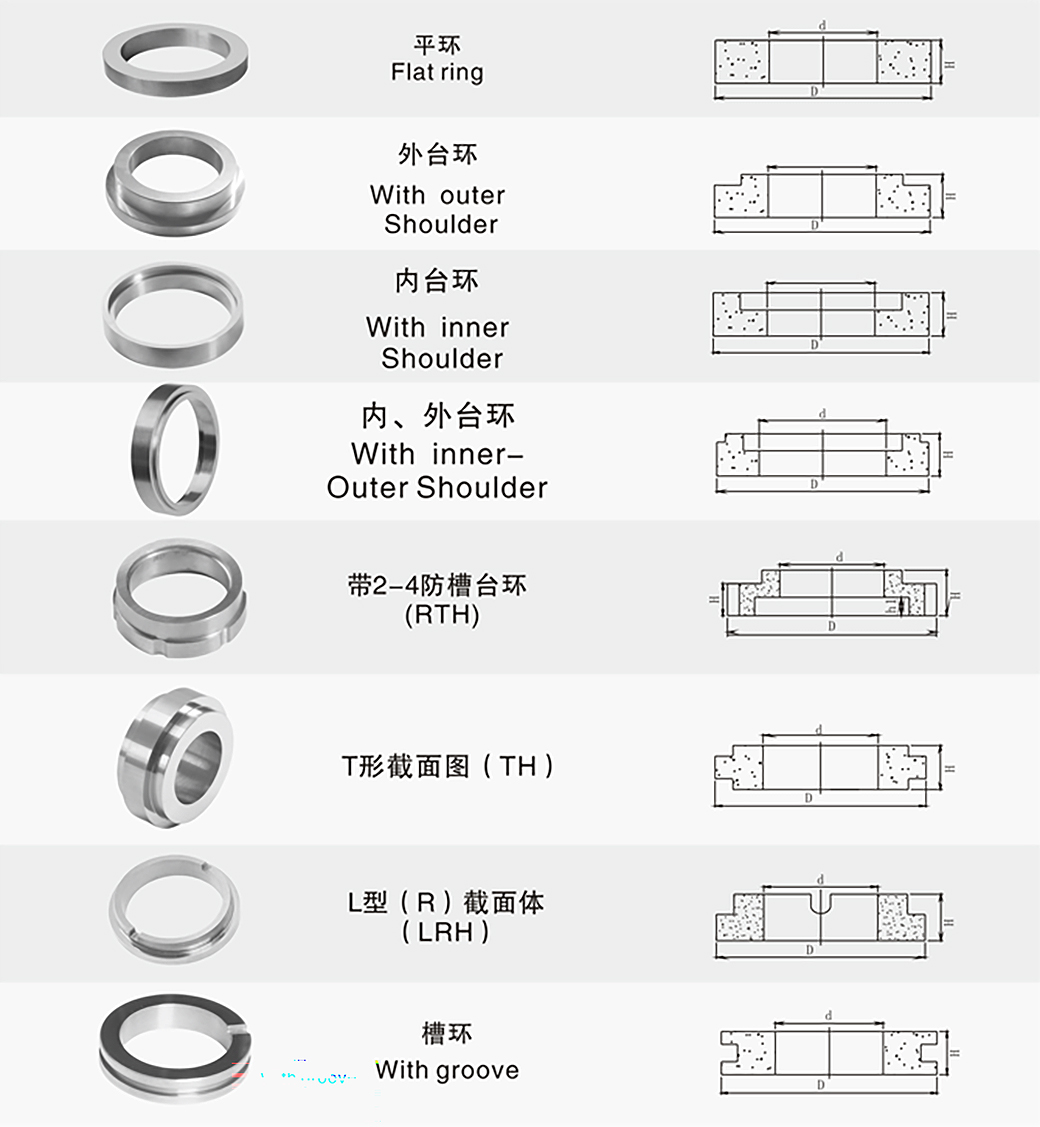

I-tungsten carbide yokutyhala ubume be-ring kwireferensi

I-tungsten carbide yokutywina i-rimensions

| D (mm) | d (mm) | H (mm) |

| I-10-500mmm | 2-400mm | 1.5-300mm |

Ibakala lezinto ezibonakalayo ze-tungsten carbide yokutywina

| Amabakala | Iipropathi zomzimba | Isicelo esikhulu kunye neempawu | ||

| Ubunzima | Ukuxinana | I-TRS | ||

| Hra | G / cm3 | N / mm2 | ||

| Cr40a | 90.5-91.5 | 14.50-14.70 | ≥2800 | Kufanelekile ukuvelisa iringi yetywina kunye nomkhono osetyenziswe kumzi-mveliso wePumps ngenxa yobuqili obukhulu kunye nokunganyangeki okuhle, |

| Cr06n | 90.2-91.2 | 14.80.00 | ≥2680 | Ikulungele ukuvelisa imikhono kunye ne-bushings esetyenziswa kwimizi-mveliso yePumps ngenxa yokunganyangeki kakuhle kunye nokunganyangeki kwe-erosion, |

Izixhobo zemveliso

Ukugaya okumanzi

Ukutshiza ukomisa

Cinezela

Cinezela

Cinezela

I-hip ye-hip

Izixhobo zokulungisa

Ukuqhuba

Ukusika ucingo

Ukugaya nkqo

I-Universal Grinding

Iplanethi igada

Umatshini wokumisa i-cnc

Isixhobo sokuhlola

Imitha yobukhuni

Umkhangi

Umlinganiso we-quadratic

Isixhobo se-cobalt

Imicroscope ye-thrografic